They are suspended by a crane from two slings and normally have two to four bottom slings attached for rigging to the load.

Pipe lifting spreader bar.

The most common lifting device bishop lifting products inc.

Find the load capacity minimum and maximum spread and headroom that fits your application.

A lifting beam is under pressure at the single lifting point and therefore subject to shear and bending while a spreader beam is designed to work under compression and spread the load out evenly over a.

High quality spreader beams from grainger help lift uneven loads and keep them level for increased safety.

Fabricates is the liftmax spreader bar.

Geometry of lifting at the each end of the hollow pipe spreader beam solved using the equations of static equillibrium a strength design design for flexural bending stress.

Steel clamps and handgrips are used to lift and turn object such as plates and beams in multiple directions.

Safe working load swl.

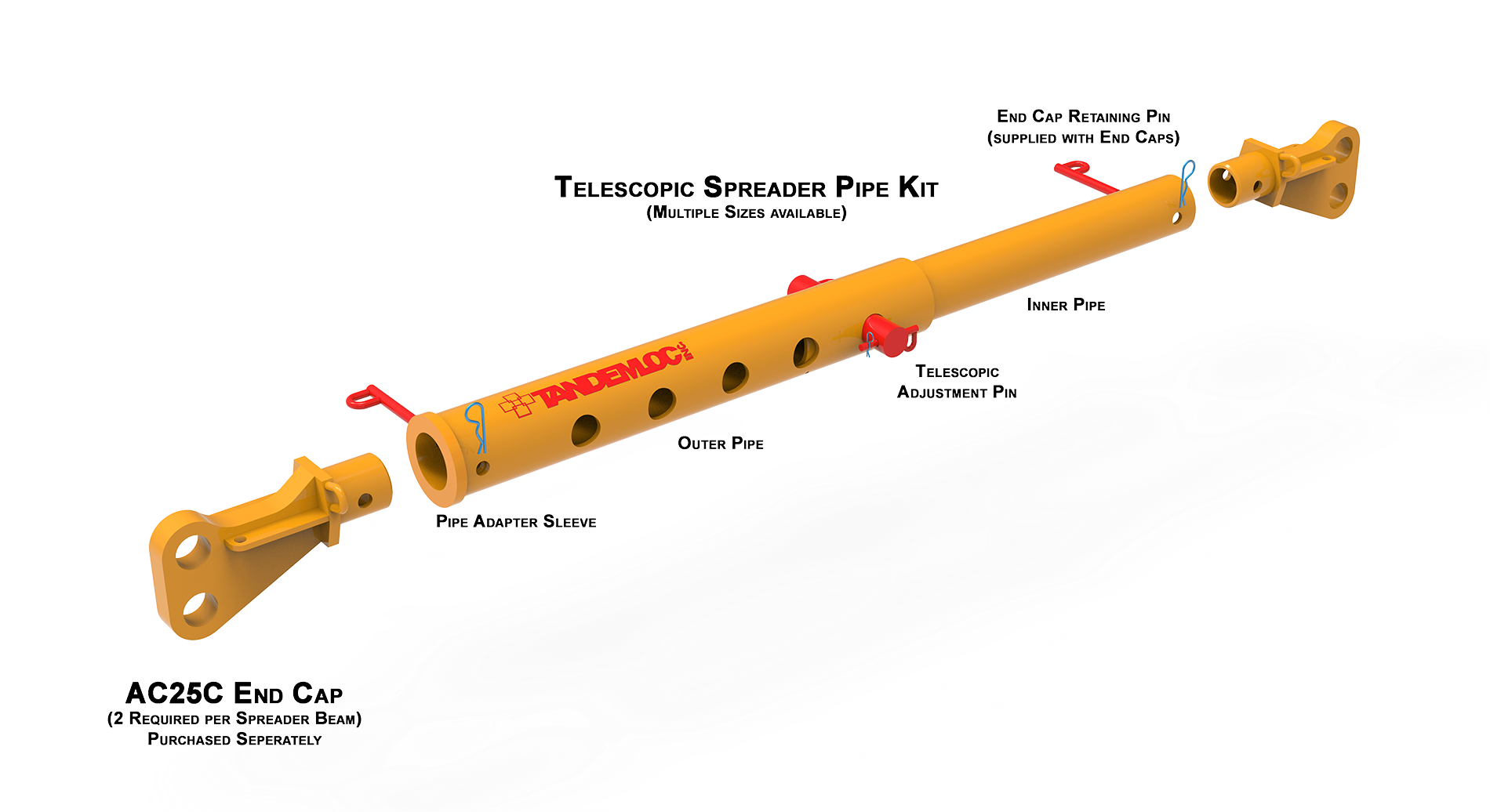

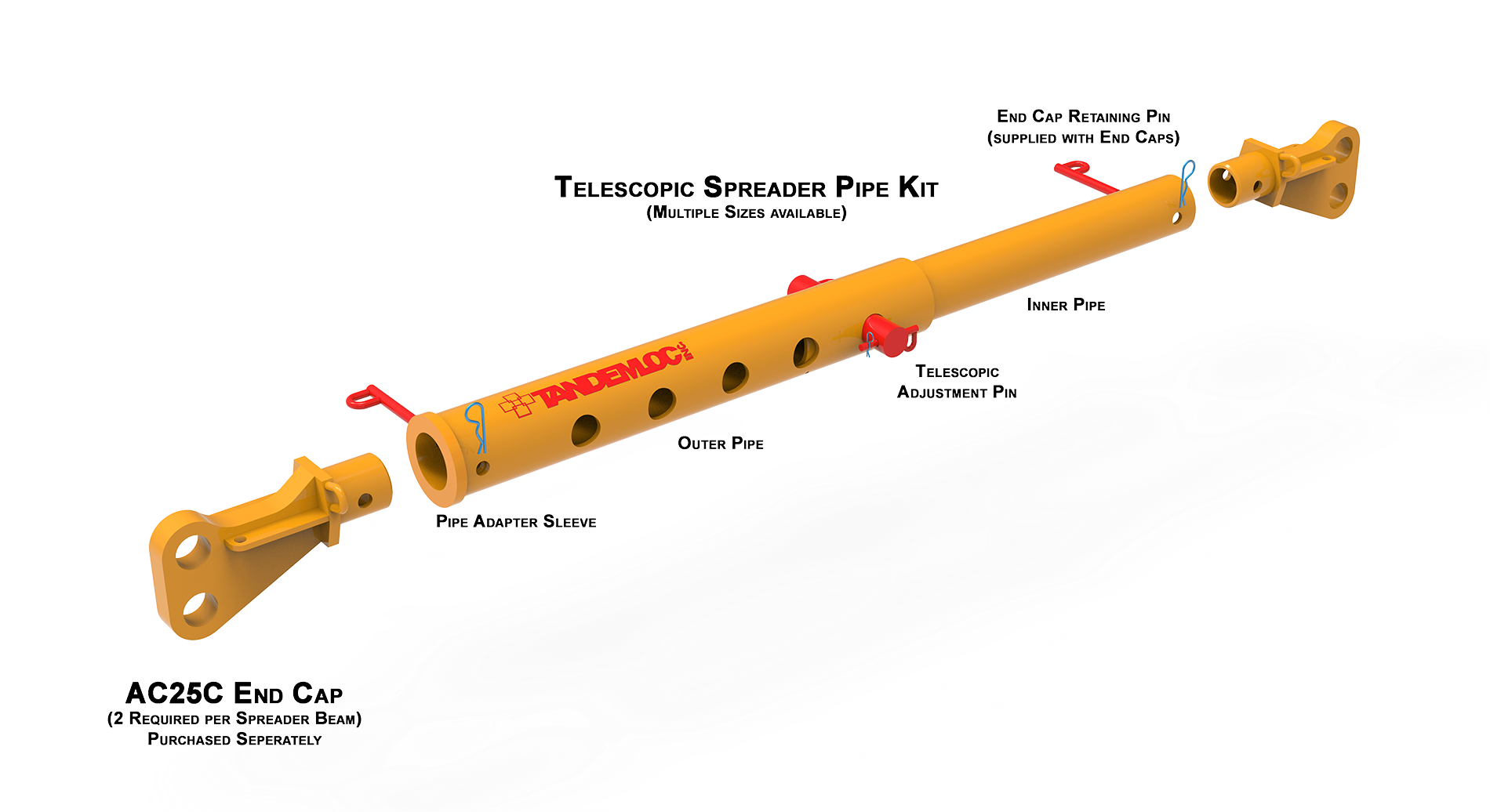

Steel and aluminum end caps and components.

Another advantage of spreader bars to lifting beams is a spreader bar is easily made adjustable in length to accommodate a range of lift spreads.

Tongs grasp drag and lift timber and poles containers pipe and round bars.

Secure a high quality affordable pipe rolling spreader bar from australia s leading lifting rigging supplier.

Fast australia wide delivery available or visit your local branch.

Choose from modular adjustable and two position spreader beams and fixed and adjustable fiberglass battery lifting beams.

Spreader beams and lifting beams keep uneven loads level.

Bar stock material positioners lift and place bar stock materials.

Due to the axial nature of the load the most efficient shape for spreader bars are square or round tubes.

Just like lifting beams spreader beams are used to widen the available lifting points on rigged loads and keep lifting slings at a 90 angle relative to the horizon.

Spreader bar lifting device calculations and design spreader bar lifting device calculations and design.

Unlike lifting beams which convert vertical lifting forces into bending forces on the beam spreader bars convert vertical lifting forces into compression forces on the beam.

The main difference between a lifting beam and a spreader bar is the design which dictates the way the force is transmitted during the lift.

Combination beams combine design elements of spreader and lifting beams which have a centred lifting point as well as lifting points on the ends of the top side of the beam.

Spreader bars are normally made out of pipe and have top and bottom lifting points on opposing ends.

It then becomes easy to add a section that will slide overtop other sections.